In the dynamic landscape of industrial operations, maintaining optimal cleanliness is not just a necessity but a strategic imperative. Traditional cleaning methods often fall short, leaving residues, wasting time, and posing environmental challenges. Enter the future of industrial cleanliness – the Industrial Laser Cleaner. Unleash the power of precision with cutting-edge technology that redefines the way you keep your workspace immaculate.

The Spark of Innovation:

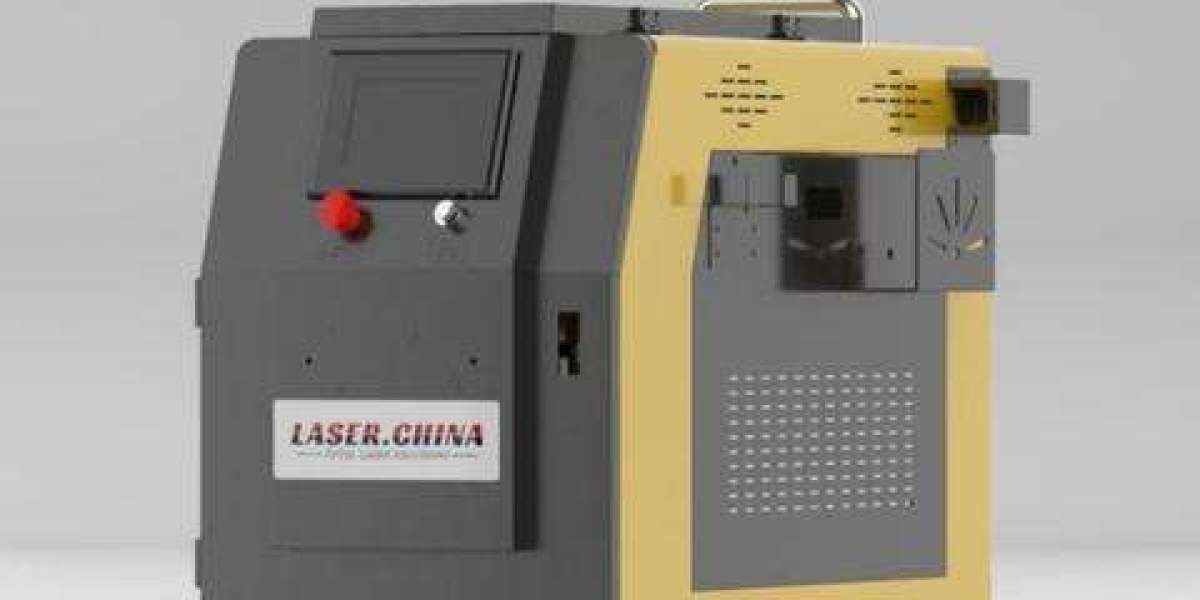

Our Industrial Laser Cleaner represents a quantum leap in cleaning technology. Gone are the days of laborious scrubbing and reliance on chemical-laden solutions. This innovative solution utilizes the power of lasers to provide unparalleled cleaning precision. Say goodbye to manual effort and hello to efficiency redefined.

How It Works:

The Industrial Laser Cleaner employs state-of-the-art laser technology to remove contaminants with unmatched precision. The laser beam interacts with the surface, instantly vaporizing and eliminating unwanted substances. This process ensures a thorough and residue-free cleaning experience, promoting a pristine environment for your industrial setting.

Key Features:

Precision Cleaning: The focused laser beam precisely targets contaminants, leaving no room for residues or missed spots.

Versatility: From rust and grease to paint and coatings, our Industrial Laser Cleaner tackles a myriad of substances, adapting to diverse industrial cleaning needs.

Environmental Friendly: Unlike traditional cleaning methods that rely on chemicals, our laser cleaner is eco-friendly, minimizing your environmental footprint.

Time Efficiency: Boost your operational efficiency with rapid cleaning cycles, reducing downtime and increasing productivity.

Cost-Effective: Long-lasting and durable, our Industrial Laser Cleaner represents a smart investment, saving you money in the long run.

Applications Across Industries:

Manufacturing: Streamline your manufacturing processes by ensuring a pristine environment, leading to improved product quality.

Automotive: Remove paint, rust, and contaminants effortlessly, restoring automotive components to their original state.

Aerospace: Maintain the highest standards of cleanliness in the aerospace industry, where precision is paramount.

Metalworking: Enhance the lifespan of metal components by eliminating rust and corrosion effectively.

Electronics: Safely remove residues and contaminants from delicate electronic components without risking damage.

Advantages Over Conventional Methods:

No Chemical Residues: Bid farewell to chemical residues that can compromise product quality or pose health risks.

Reduced Downtime: The speed and efficiency of our Industrial Laser Cleaner translate into reduced downtime, maximizing your operational output.

Enhanced Safety: With minimal manual involvement, the risk of accidents and injuries associated with traditional cleaning methods is significantly reduced.

Consistent Results: Achieve consistent and uniform cleanliness across surfaces, ensuring a high standard of quality in your operations.

Conclusion:

Investing in our Industrial Laser Cleaner is not just a step into the future; it's a leap towards efficiency, precision, and sustainability. Revolutionize your industrial cleaning processes and experience the transformative power of laser technology. Embrace a cleaner, greener, and more efficient future with the Industrial Laser Cleaner – where precision meets performance!