Introduction

It is impossible to overestimate the significance of enamel and wire coating in the ever changing field of industrial advances. These procedures are essential to improving the conductivity, longevity, and general performance of wires, which makes them useful across a range of sectors. One company, Harman Bawa Pvt. Ltd., sticks out for its dedication to quality as we delve into the nuances of wire and enamel coating. The importance of wire and enamel coating will be discussed in this blog, along with some of Harman Bawa Pvt. Ltd.'s creative solutions.

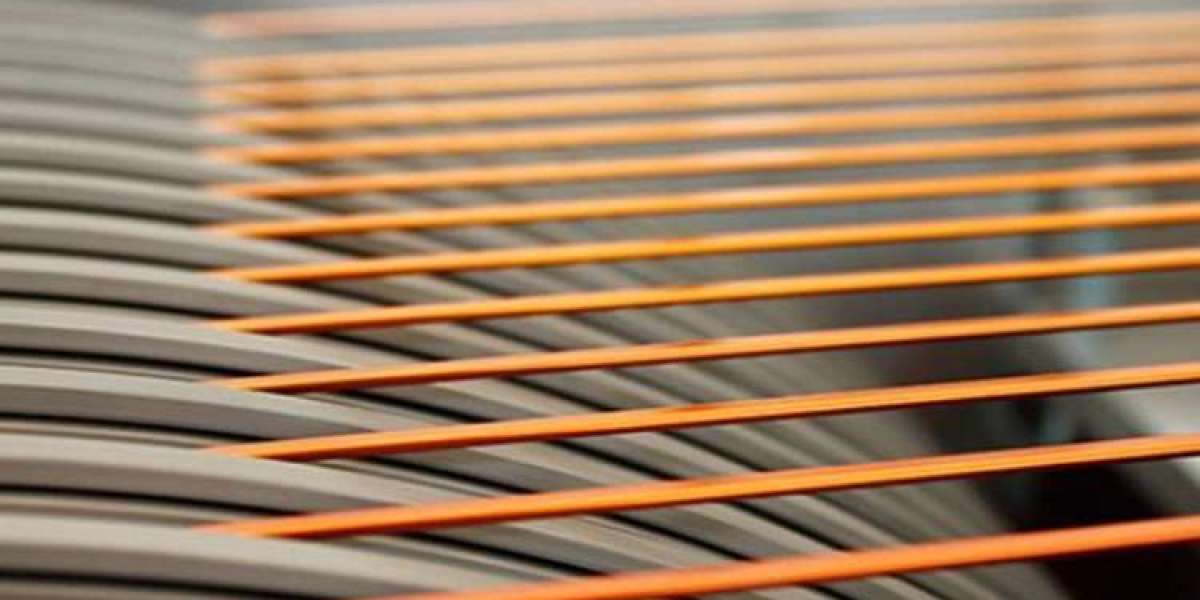

Understanding Wire Coating

The practice of applying a protective layer on wires to shield them from environmental elements, abrasion, and corrosion is known as wire coating. The principal aim is to augment the durability and dependability of cables, guaranteeing their peak efficacy even under demanding circumstances.

Harman Bawa Pvt. Ltd.: A Pioneer in Wire Coating

Harman Bawa Pvt. Ltd. has become a prominent player in the wire coating industry by utilizing state-of-the-art technology and a dedication to excellence. The organization has a well-established track record of delivering creative solutions and is highly regarded for its proficiency in strengthening wires' durability through rigorous coating procedures.

The Wire Coating Process at Harman Bawa Pvt. Ltd.

At Harman Bawa Pvt. Ltd., the wire coating process is a painstakingly organized and carried out set of procedures that guarantee the finest caliber. The organization uses cutting edge equipment and a group of knowledgeable experts to provide outstanding wire coating services. The procedure consists of:

- Surface Preparation: To guarantee the best possible adhesion of the coating material, the wire surface is carefully cleaned and prepped prior to coating application.

- Choice of Coating Material: Harman Bawa Pvt. Ltd. is proud to provide a wide selection of coating materials that are suited to the unique needs of various industries. A thorough evaluation of variables including conductivity, flexibility, and resilience to environmental influences is part of the selecting process.

- Methods of Application: The business uses sophisticated application methods, including as dip coating, spray coating, and extrusion coating, based on the special qualities of the wire and the intended use.

- Curing and Quality Control: The wires go through a curing process to increase the coating's longevity once it has been applied. Every step of the process is subject to strict quality control procedures to guarantee that the coated wires meet or surpass industry requirements.

Enamel Coating: Enhancing Electrical Performance

Enhancing wires' electrical characteristics is the primary goal of enamel coating, a type of specialty wire coating. Enamel is applied to the wire's surface during this operation as a sort of insulating substance. Electrical components, transformers, and motors are among the many products that require enamel coating.

Harman Bawa Pvt. Ltd.: The Epitome of Enamel Coating Excellence

Regarding enamel coating, Harman Bawa Pvt. Ltd. is a notable innovator in the field. The company's dedication to accuracy and innovation has led to the creation of enamel coating solutions that raise the bar for electrical performance.

The Enamel Coating Process at Harman Bawa Pvt. Ltd.

Superior electrical insulation qualities are ensured in the coated wires by Harman Bawa Pvt. Ltd.'s methodical enamel coating process. The steps involved in enamel coating are as follows:

- Formulation of Enamel: The business makes research and development investments to create enamels that have precisely the right amounts of adhesion, heat resistance, and electrical insulation.

- Application Techniques: To apply enamel coatings precisely and consistently, Harman Bawa Pvt. Ltd. makes use of sophisticated application techniques like the continuous extrusion process.

- Heat Curing: To improve the adhesion between the enamel and the wire surface, the wires go through a heat curing process after the enamel has been applied.

- Electrical Testing: To make sure the enamel-coated wires fulfill the necessary electrical insulation requirements, extensive electrical testing is carried out.

Harman Bawa Pvt. Ltd.: A Vision for Sustainable Coating Solutions

Apart from its exceptional skills in enamel and wire coating, Harman Bawa Pvt. Ltd. is dedicated to environmental responsibility and sustainability. In an effort to promote a more sustainable and environmentally friendly future, the company actively investigates eco-friendly coating materials and procedures.

Industry Applications of Harman Bawa Pvt. Ltd.'s Coating Solutions

Applications for Harman Bawa Pvt. Ltd.'s wire and enamel coating solutions can be found in a variety of industries, including:

- Electronics and Electrical Manufacturing: The production of dependable and effective electrical components depends on Harman Bawa Pvt. Ltd.'s wire coating solutions.

- Automotive: For a variety of uses, including wiring harnesses and sensors, the car sector depends on robust and well-coated wires.

- Aerospace: The durability and functionality of vital wiring systems are guaranteed by Harman Bawa Pvt. Ltd.'s coating solutions in this industry, where dependability is crucial.

- Renewable Energy: As the globe moves more and more toward using renewable energy sources, there is an increasing need for high-performance coated wires in solar panels and wind turbines.

Conclusion

Harman Bawa Pvt. Ltd. has been a leader in innovation and dependability in the ever-changing wire coating and enamel coating industries. The company is unique in the industry because of its dedication to sustainability, cutting-edge technology, and quality. With innovative solutions that raise the bar for wire and enamel coating, Harman Bawa Pvt. Ltd. continues to be at the forefront of industry evolution. By means of an efficient fusion of proficiency and commitment, the organization keeps influencing the direction of coated wire solutions, promoting quality and dependability in a variety of industries.