Computer numerical control (CNC) is an automated machining process that transforms raw materials into finished parts. It can produce a wide range of shapes with high precision and efficiency. It is important to understand what to look for when buying a CNC machine tool. Choosing the right tool for your business will require a thorough understanding of your production requirements and budget plan.

Used CNC Machinery

A used cnc equipment for sale can be a great buy if you have clear goals and are prepared to take a little risk. Evaluate your CNC goals carefully, then narrow your search to include machines with features and capacities you can use now while keeping future growth in mind. Look for user groups in your area and attend CNC classes to talk with people about their machines and get practical information.

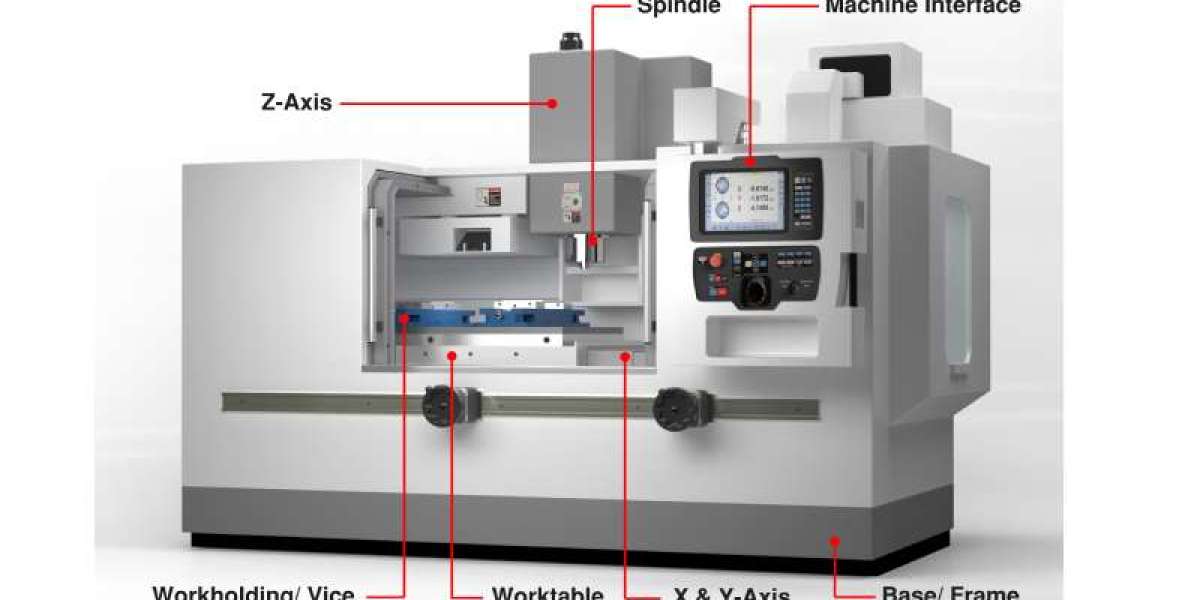

Also, pay attention to whether the CNC can be upgraded as you learn to operate it. Adding a fourth axis—rotary work, similar to what you’d do on a lathe—can significantly enhance your capabilities. Some benchtop models can do rotary work but need to be plugged into a computer to operate, while others have a built-in fob that allows you to plug in a PC. Check the machine’s capacity for cutting large pieces like signs, door panels, or cabinet parts. Keep in mind that a spoilboard, which you use to cut through thick material, reduces the stated Z-axis travel of the machine (photo, below). And make sure the machine can accommodate the height of the tool you plan to use.

Used CNC Equipment

A CNC machine can act like a router, drill press, jigsaw, table saw and more all at once. They allow for a level of accuracy that would be difficult, if not impossible, to achieve manually. They are used in wood working to cut, shape and drill, in metal fabrication to mill, tap and cut as well as in electrical machining for coil winders and soldering.

When it comes to purchasing a CNC machine, you need to make sure it is the right model for your specific needs. Research and comparison shopping is essential to ensure you find the right make and model. New machines come with the latest technology and tend to be more advanced than older models. Some brands are known for their quality and reliability. A good example is Toyoda, which is known for its high-quality CNC machines. However, they are pricier and have limited parts availability in the US. For this reason, it is best to consider a second-hand machine from a different brand. One can visit the site to get complete insights about cnc machine tools for sale .

Buy Used CNC Machines Surplus Record

Purchasing used CNC equipment can significantly increase production capacity for a business without the expense of paying for expensive new machinery. However, before making any purchases, businesses should carefully inspect the machine to ensure that it is in good working condition. It is important to look for signs of wear and tear, as well as to consider how many hours the machine has logged.

When evaluating a used CNC machine, it is also a good idea to ask the seller for documentation of its maintenance history. This can provide insight into how well it has been taken care of and will help determine its reliability. A used Haas CNC mill is an excellent choice for companies that require a versatile machine for cutting and shaping materials. The brand is known for its economical construction and simple-to-use controls. Haas manufactures a variety of CNC machines, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and CNC lathes.

CNC Masters

CNC machines transform a block of material into a specific shape by following coded program instructions, instead of a manual operation by a human operator. This helps to ensure consistency in production and reduces the risk of workplace accidents. Unlike standard industrial milling tools, which require trained machinists to operate, these cnc machine tools are computer-led and can produce high-quality output with minimal effort. They are also efficient, cost-effective and can be used in many different industries including aerospace, medical and electronics.

Educational CNC machines are built for quality over long production runs, so they can withstand the unintentional mistreatment that students often inflict upon them. A rugged CNC lathe, such as the 1440 gear head CNC turning center from CNC Masters, is a good option for community colleges and vocational schools. It is easy to learn and comes with a variety of features that help to create a real-world learning experience for your students.