The construction industry is on the cusp of a transformative era, driven by a surge in demand for composite insulated panels (CIPs). These innovative building components, composed of an insulating core sandwiched between durable facings, are rapidly reshaping the market landscape. This article delves into the key factors propelling the CIP market boom, explores the diverse applications and benefits of these panels, and unveils the exciting potential that lies ahead.

Market Overview

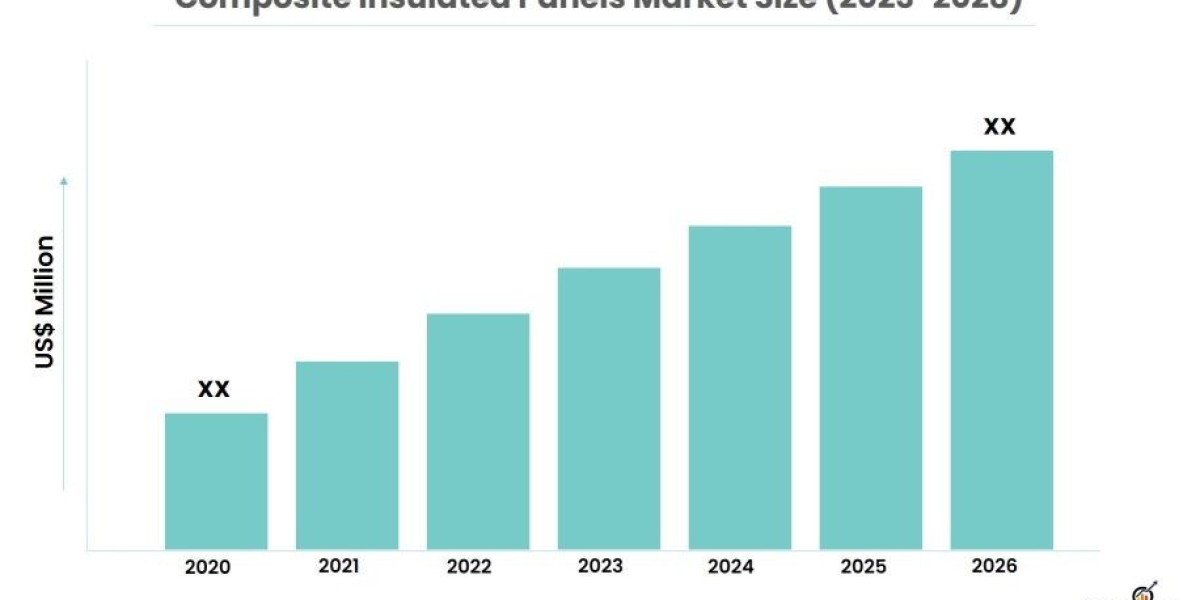

According to Stratview Research, The global composite insulated panels market size is estimated to grow at a CAGR of 6% during the forecast period of 2021-2026.

A Confluence of Drivers: Fueling Market Growth

Several factors are converging to create a perfect storm for the CIP market:

- Sustainability Imperative: A growing global focus on sustainability is prompting a shift towards eco-friendly construction practices. CIPs, with their exceptional thermal insulation properties, contribute significantly to energy efficiency, leading to reduced energy consumption and a smaller environmental footprint. This aligns perfectly with the rising demand for green buildings.

- Technological Advancements: Continuous advancements in manufacturing technologies are leading to the development of new and improved CIPs. Innovations in core materials and facings are resulting in enhanced performance characteristics, including superior insulation values, increased fire resistance, and improved acoustics. This continuous improvement broadens the appeal of CIPs for a wider range of applications.

- Government Regulations: Governments around the world are implementing stricter regulations to promote energy-efficient buildings. These regulations, coupled with growing environmental concerns, are creating a favorable environment for the adoption of CIPs. As the demand for sustainable building materials rises, the CIP market is well-positioned to reap the benefits.

Beyond Efficiency: Unveiling the Multifaceted Benefits of CIPs

The benefits of CIPs extend far beyond their role in energy savings. These versatile panels offer a multitude of advantages that cater to diverse construction needs:

- Faster Construction: CIPs are prefabricated, arriving at the construction site ready for installation. This significantly reduces construction time compared to traditional methods, leading to faster project completion, lower labor costs, and minimized disruption to occupied spaces.

- Enhanced Durability: CIPs are built to withstand harsh weather conditions, including extreme temperatures, heavy winds, rain, and snow. Additionally, their inherent strength makes them resistant to impact damage, ensuring long-lasting building performance with minimal maintenance requirements.

- Improved Acoustics: Certain CIP configurations boast sound-dampening core materials, contributing to a quieter indoor environment, a significant benefit for commercial, industrial, and educational facilities.

- Design Flexibility: CIPs come in a wide variety of colors, finishes, and textures, allowing architects to achieve their desired aesthetics without compromising on performance. This design flexibility caters to the evolving needs of modern architecture.

- Superior Fire Safety: Specific CIP configurations are designed with fire-resistant properties, hindering flame spread and improving building safety during fire emergencies. This provides peace of mind for building owners and occupants.

A Spectrum of Applications: Unveiling the Versatility of CIPs

The versatility of CIPs is another key driver of market growth. These panels are not limited to a single application; their adaptability makes them suitable for a wide range of construction projects, including:

- Residential Construction: CIPs offer a faster, more energy-efficient solution for building exterior walls and roofs in residential projects.

- Commercial Buildings: The speed and efficiency of CIPs make them ideal for constructing office buildings, retail spaces, and hotels. Their superior thermal performance also translates to cost savings on energy bills.

- Industrial Facilities: CIPs are well-suited for warehouses, cold storage facilities, and industrial plants due to their durability, fire resistance, and exceptional insulation properties. These features create a controlled environment for sensitive materials and products.

- Prefabricated Structures: The prefabricated nature of CIPs makes them ideal for constructing prefabricated buildings like modular homes, temporary structures, and disaster relief shelters.

Market Segmentation and Key Players

The CIP market can be segmented by various factors, including:

- Core Material: Polyurethane, mineral wool, and expanded polystyrene are some of the most common core materials used in CIPs, each offering unique properties.

- Facing Material: Metal (steel or aluminum), fiberglass, and composite materials are commonly used as facings, providing durability and aesthetic options.

- Application: The market is segmented by the specific application of the CIPs, such as residential, commercial, industrial, and cold storage.

Major players in the CIP market include Kingspan Group, Tata Steel, ArcelorMittal, Mitsubishi Chemical Corporation, and Sekisui Chemical Co., Ltd. These companies are constantly innovating and expanding their product offerings to cater to the growing demand.