Glass Jars Production Cost are widely used for packaging various food products, beverages, cosmetics, pharmaceuticals, and other consumer goods. Understanding the production costs associated with manufacturing glass jars is essential for glass manufacturers, packaging companies, and businesses involved in the supply chain. In this comprehensive analysis, we will delve into the factors influencing Production Cost of Glass Jars, explore cost trends, and discuss strategies for optimizing manufacturing processes.

Understanding Glass Jars Production Costs

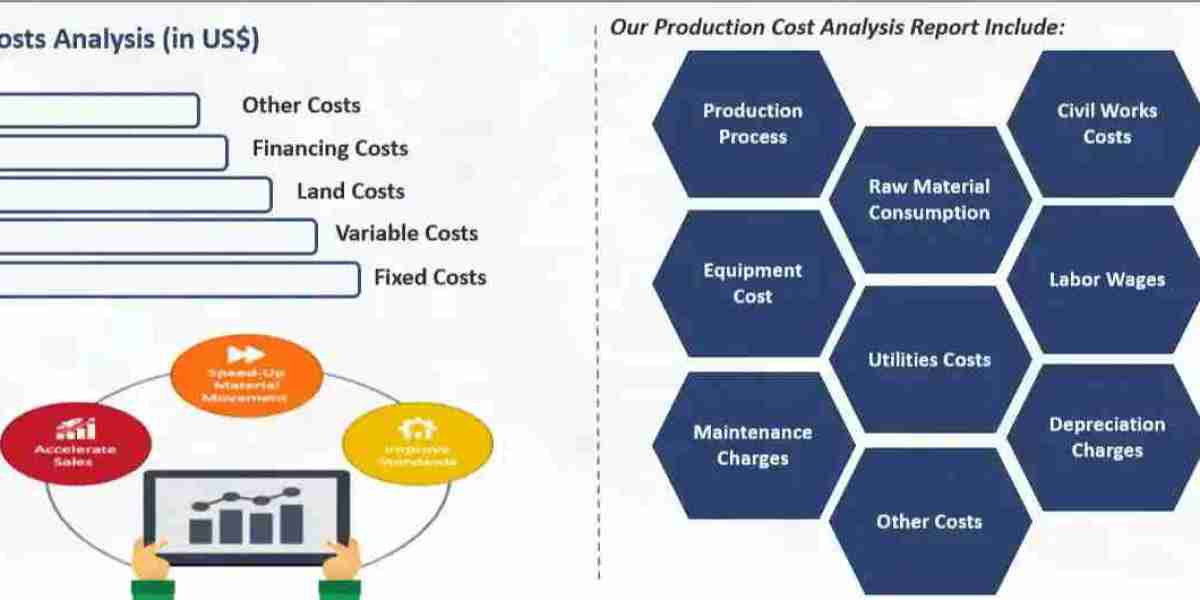

The production costs of glass jars involve several components, including raw materials, energy consumption, labor, equipment maintenance, and overhead expenses. Here are some key factors influencing glass jars production costs:

1. Raw Materials:

- Cullet (Recycled Glass): The use of recycled glass (cullet) as a raw material can significantly reduce production costs compared to using virgin materials. However, the availability and quality of cullet may vary, impacting material costs.

- Silica Sand, Soda Ash, and Limestone: These primary raw materials are melted together to form glass. Fluctuations in the prices of these materials can affect overall production costs.

2. Energy Consumption:

- Natural Gas and Electricity: Glass melting furnaces consume large amounts of energy. Energy-efficient technologies and practices can help minimize energy costs and improve production efficiency.

3. Labor Costs:

- Skilled and Unskilled Labor: Glass manufacturing involves various skilled and unskilled laborers, including glass blowers, machine operators, quality control inspectors, and maintenance personnel. Labor costs can vary depending on factors such as location, labor laws, and skill levels.

4. Equipment and Maintenance:

- Furnaces and Machinery: Glass manufacturing equipment, such as furnaces, molds, annealing lehrs, and inspection machines, require regular maintenance and occasional upgrades. Capital investments in modern equipment can enhance productivity and quality while reducing maintenance costs.

- Tooling and Molds: The design and maintenance of molds and tooling for shaping glass jars can affect production costs and lead times.

5. Overhead Expenses:

- Facility Costs: Expenses related to facility rent or mortgage, utilities, insurance, and property taxes.

- Administrative Costs: Costs associated with management, administration, sales, marketing, and other overhead functions.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/glass-jars/request-sample

Trends in Glass Jars Production Costs

Several trends influence glass jars production costs, including raw material prices, energy efficiency measures, technological advancements, and market demand dynamics. Here are some notable trends:

1. Sustainability and Recycling:

- Growing awareness of environmental issues has led to increased emphasis on sustainability in the glass packaging industry. Recycling initiatives and use of recycled cullet help reduce raw material costs and environmental impact.

2. Energy Efficiency:

- Glass manufacturers are investing in energy-efficient technologies, such as oxy-fuel furnaces, waste heat recovery systems, and advanced insulation materials, to reduce energy consumption and lower production costs.

3. Automation and Digitalization:

- Automation and digital technologies, such as robotics, sensors, and data analytics, are being deployed to optimize production processes, improve quality control, and reduce labor costs.

4. Market Demand and Customization:

- Changing consumer preferences and demand for personalized packaging solutions drive the need for flexibility and customization in glass jar production. Manufacturers must balance cost efficiency with the ability to offer diverse product options.

Strategies for Optimizing Glass Jars Production Costs

To enhance cost efficiency and competitiveness in glass jar manufacturing, companies can implement various strategies:

1. Raw Material Optimization:

- Source high-quality cullet and negotiate favorable contracts with suppliers to ensure consistent supply and pricing stability.

- Explore alternative raw materials and formulations to mitigate the impact of price fluctuations in traditional inputs.

2. Energy Management:

- Invest in energy-efficient equipment and technologies to reduce fuel consumption and greenhouse gas emissions.

- Implement energy management systems and monitoring tools to track energy usage, identify inefficiencies, and optimize operations.

3. Process Optimization:

- Streamline production processes, minimize downtime, and reduce waste through lean manufacturing principles and continuous improvement initiatives.

- Invest in training and upskilling employees to enhance productivity and ensure optimal use of resources.

4. Supply Chain Efficiency:

- Collaborate closely with suppliers to streamline logistics, reduce lead times, and optimize inventory management.

- Explore local sourcing options to minimize transportation costs and enhance supply chain resilience.

Conclusion

In conclusion, analyzing and optimizing glass jars production costs is essential for manufacturers to remain competitive in the packaging industry. By understanding the key cost drivers, monitoring industry trends, and implementing effective cost-saving strategies, glass manufacturers can enhance profitability, improve sustainability, and meet evolving customer demands. Continuous innovation, investment in technology, and collaboration across the supply chain are critical to achieving long-term success in the glass packaging market.